Oven oops

Date: September-December 2023

Course: Object - Atlas 3300

Context: Identify a personal “pet peeve,” analyze the real-world conditions around it, and develop a physical solution supported by microcontroller technology.

Goal: Create a device that helps prevent people from accidentally leaving the oven on by: tracking cook time, displaying clear messages, providing visual signals, making an intuitive and easy to interact with alert system, ensuring safety while remaining low-profile and user-friendly

Tools Used: SketchUp, Epilog Laser Cutter, patience, perseverance, and industrial levels of stubbornness

Timeline: Full-semester project (16 weeks)

Weeks 1–5 (iteration 1): Electronics fundamentals, Arduino basics, circuitry practice

Weeks 6–16 (iteration 2): Designing, prototyping, programming, and assembling Oven Oops

Overview

Oven Oops is an Arduino-based alert system designed to solve a very real household problem: my roommate repeatedly left the oven on after cooking. Over a 16-week semester, I engineered a fully functional device that uses timers, LED indicators, a remote-controlled interface, and a screen-based messaging system to notify users when the oven has been left on too long.

The project combines skills in microcontroller programming, interface design, rapid prototyping, iterative electrical engineering, physical fabrication, and everyday problem solving.

The result is a quirky, functional, and technically ambitious device that evolved dramatically from its first prototype — moving from simple buttons and a countdown timer to a remote-controlled user interface with a Neopixel temperature gauge.

Process

1. Identifying the Pet Peeve

The project began with a simple but serious problem:

My roommate frequently left the oven on without realizing it.

I wanted a device that was:

Easy to understand

Impossible to ignore

Helpful without being annoying

Clearly visible from across the kitchen

This guided every design decision moving forward.

2. Early Prototyping & Circuit Fundamentals

Before beginning the device, we spent five weeks building foundational skills in:

LED behavior

Circuit wiring

Button input logic

Debugging loops and conditionals

Microcontroller communication

During this phase, I experimented with small breadboard setups that tested timing logic and alert patterns. These early explorations gave me the confidence for the first functional prototype.

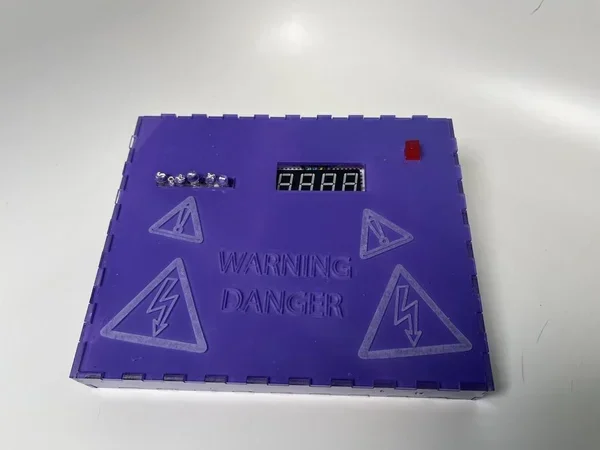

Iteration 1 – basic timer and buttons

(Low- to mid-fidelity: functionality first, looks second)

Features

Two physical push buttons (set time + start)

Basic countdown timer

LED or buzzer alert

Simple printed circuitry on a breadboard

Goals of Iteration 1

Get timing logic working

Establish a minimal viable version

Understand how to communicate alerts effectively

Test user flow (button press → timer running → alert)

Challenges

Debouncing buttons

Timing accuracy

Understanding interrupt flow

Making sure alerts were noticeable but not obnoxious

Result

A functional, ugly-but-effective prototype that proved the concept:

Users could start a cook timer and receive an alert when the time was up.

This foundation paved the way for a more ambitious second iteration.

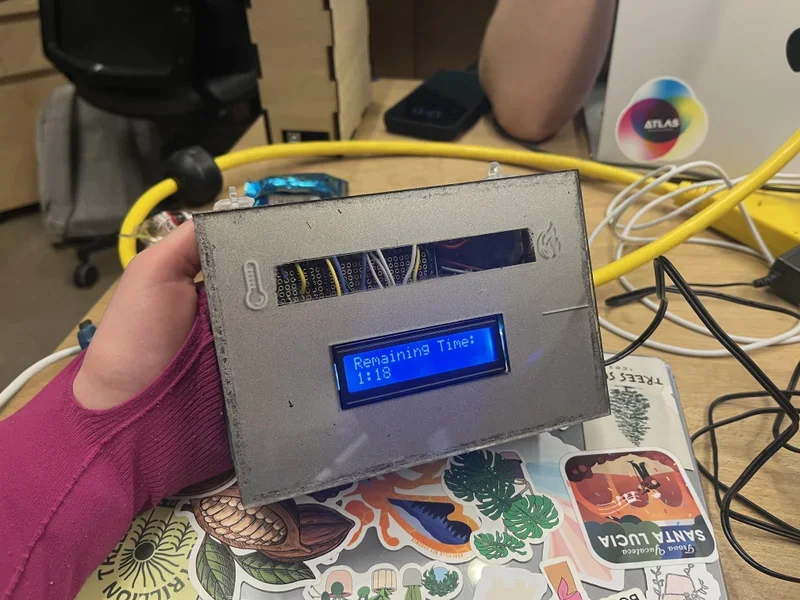

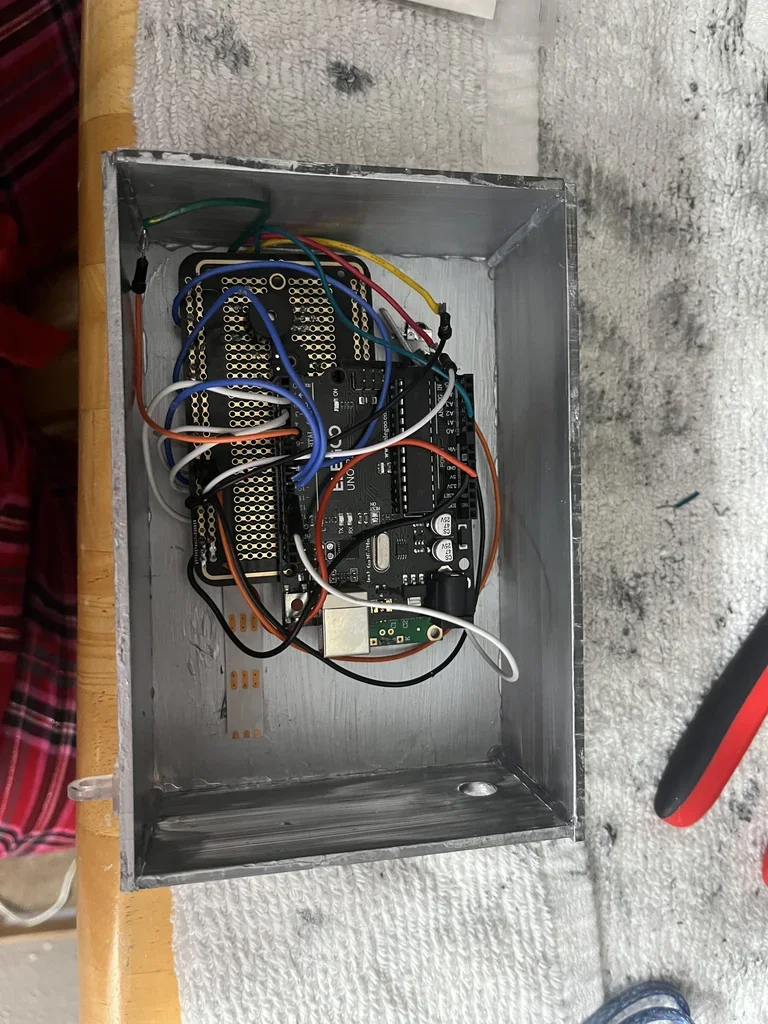

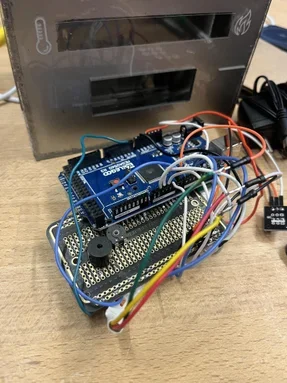

Iteration 2 — Final System

This was the big leap — combining everything I learned from electronics fundamentals and the first prototype into a polished, multi-component device.

New Features

Remote-controlled interface (IR remote)

OLED/LCD screen with written alerts (e.g. “Oven is ON,” “Time’s Up!”)

Animated Neopixel temperature/status gauge

Cleaner timer logic

More intuitive interactions

Stronger reliability and user-friendly messaging

Why These Changes?

Moving to a remote allowed:

No physical interaction with the device

Cleaner UI

Greater flexibility in setting or resetting the timer

The screen allowed:

Clear communication (“Oven Still On!”)

Timer display

Status changes based on user input

The Neopixel gauge added:

Ambient, across-the-room visibility

“Heat” color progression (blue → green → yellow → red)

A fun, expressive design element

What I Improved from the First Prototype

Removed all wired external buttons

Reorganized the code to be modular

Added user-friendly messages

Created color-coded signals

Solved timing inconsistencies

Upgraded wire organization + stability

Final Performance

The device successfully tracked oven use

Alerts displayed clearly on the screen

Colors changed based on time

Remote input worked flawlessly

All components synchronized in real-time

The system addressed the original pet peeve effectively

This iteration represents the most complex Arduino project I’ve built — integrating multiple libraries, input systems, and universal feedback channels into one cohesive device.

Outcome

A fully functioning Arduino device that:

Helps prevent accidental oven misuse

Is user-friendly and visible

Represents significant technical growth

Moves seamlessly between multiple input and output systems

Solves the original pet peeve in a fun and effective way

The device is not only functional — it’s genuinely helpful.

Reflection

The project was both challenging and incredibly rewarding. While the final device may not be as visually refined as I hoped (due to so much time going into electrical optimization), the underlying engineering represents a major technical milestone for me.

It taught me to:

Iterate thoughtfully

Accept imperfections

Learn from each step

Build with real-life constraints in mind

And perhaps most importantly:

I now know how to build functional microcontroller systems from scratch.

What I learned

This project reaffirmed something important:

I love designing solutions to everyday annoyances.

Oven Oops made me realize how much I enjoy blending creativity with electronics — and how satisfying it is to see something functional emerge from wires, code, and problem-solving.

It strengthened my confidence in electrical design and opened the door for future Arduino-based projects.