3D Platypus

Date: March 2024

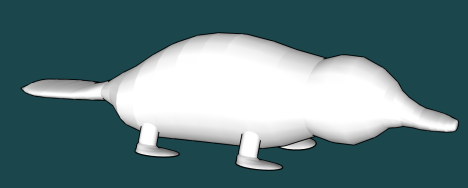

Context: Digital fabrication class assignment in creating slot-based 3D sculptures. Turn a fully organic shape into a cleanly sliced, fabricatable, planar geometry without losing its identity.

Goal: To digitally model an animal, slice it into planar cross-sections, and fabricate the interlocking parts using laser cutting. I chose a platypus, not because it is a simple geometric shape, but because my dad loves them.

Tools Used: SketchUp, Epilog Laser Cutter, patience, perseverance, and industrial levels of stubbornness

Class: Form - Atlas 3200

Overview

Process

1. Choosing the Animal:

I selected a platypus because:

My dad loves them

I thought it would be cute

First realization:

Platypuses do NOT convert well into simple geometric forms. Everything about the head, tail, and body proportions fought back.

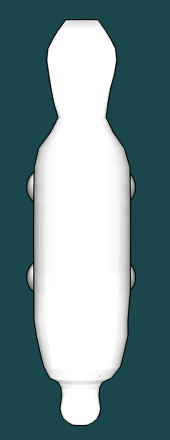

3. Slicing the Model

Using the slicing method shown in class:

Created planes in a repeating pattern

Learned the importance of offsetting slices by exactly 300 mm

Realized too many slices created a blob, and too few erased the platypus entirely

Key learning moment:

“I realized why he moved them 300 mm—lining them up so well is my savior.”

To preserve the general form, I reduced slice count but accepted the consequence:

The platypus silhouette became slightly more rat-shaped with fewer sections.

5. Preparing Laser Files

To preserve correct scale, I kept a 10” x 12” bounding rectangle around the entire layout. This ensured DXF import scaling errors could be corrected by resizing the rectangle back to proper dimensions.

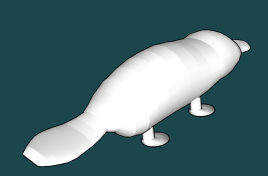

First Cut Attempt = Failure

I forgot to erase internal intersection lines

Two pieces were accidentally sliced in half by the laser

Luckily, there was enough material margin to recut those pieces properly.

Second Cut Attempt = Success

All pieces cut cleanly, with only one issue left:

Beak Problem: The very front of the platypus lacked a matching slot. I forgot to generate it. One side had a slot, the other didn’t. I accepted it and kept it asymmetrical.

Outcome

A fully fabricated, slotted 3D sculpture of a platypus, constructed entirely from flat pieces cut on an Epilog laser.

Despite modeling challenges, the final object:

Assembles correctly

Stands on its own

Reads as a stylized animal form

Holds sentimental value as a gift

It satisfied all assignment requirements and demonstrated mastery of:

Organic modeling in SketchUp

Digital slicing

Slot joint design

Laser fabrication workflow

Error recovery + iteration under pressure

Personal Insight

I discovered that even when every step feels tedious, the final object can still be meaningful, delightful, and full of personal character.

And most importantly—my dad loved it.

What I Learned

Organic shapes are difficult to model in geometric CAD tools

Slice quantity dramatically affects recognizable form

Slotting requires rigorous attention to alignment

Intersect Faces is a lifesaver

Laser cutting requires meticulous cleanup before export

Always keep a scaling reference rectangle

Perfection is not required for success—functionality and craft matter more

Reflection

This project taught me both the technical discipline of digital fabrication and the emotional process of working through a difficult, sometimes frustrating design challenge.

From a worm-shaped beginning to a vaguely platypus-shaped end, I learned how to:

Adapt

Compromise

Troubleshoot

And laugh at the process

Even when the final result leaned more “rat” than “platypus,” I was proud of the craftsmanship and the daily growth it demanded.

2. Early Modeling

Using SketchUp, I attempted to sculpt the base body using push/pull and curved surfaces.

Challenges included:

Circular body with subtle tapering

The beak/snout hybrid shape

Flattened tail

Maintaining symmetry

Quote from my journal:

“It is just looking like a worm, a weird worm.”

4. Slotting the Pieces - this was the most tedious phase.

Workflow:

Use Intersect Faces to generate slot intersection geometry

Mark every slot manually

Ensure slots meet cleanly in both directions

Remove unnecessary lines

Resize cutouts to fit material thickness

Mental state during this phase:

“I think I would cry without the intersect planes tool.”

“I hate every single step of this project.”

But… I completed it successfully.

6. Assembly

Assembled the slotted pieces into a standing figure:

Body slices interlocked seamlessly

Vertical and horizontal slices formed stable structure

The head and beak joined despite the missing slot

Tail and body proportions read as “platypus enough”

The final result: Cute. Recognizable. Slightly rodent-coded. But charming.